The pollution problem of disposable plastics is becoming more and more serious. It has become a common understanding in our daily life to protect the ecological environment and sustainable development. Recycling of packaging materials is one of the important ways to solve this problem. The company is mainly engaged in the recycling, processing, production and sales of PC, PS, pet, PP, ABS, POM, PE, PA and other plastics. It is a large-scale PCR material enterprise with GRS certification (global recycling standard) in China, with an annual production capacity of 210000 tons. It is a reliable supplier of environmental protection plastics!

PCR refers to the recovery of resin after consumption. In environmental protection packaging materials, PCR is considered to be an effective and suitable high-quality choice in the field of recycled plastics. As a kind of recycled resin products, the quality of PCR materials varies. How to ensure the quality of products? This requires the third-party monitoring. GRS checks the production scale and qualification of PCR manufacturers, and issues GRS certification only when they meet the standards. Enterprises with GRS certification are qualified suppliers with guaranteed quality of PCR.

2、 PCR material production process

#PCR material production includes manual roughing, machine automatic sorting, cleaning and modified granulation.

#Manual roughing mainly distinguishes the used plastic products according to different colors and materials;

#Machine automatic sorting is the use of near-infrared automatic sorting production line, large-scale electrostatic separation production line, color sorter and other equipment to further classify materials by color and material;

Cleaning is to remove stains, electrodeposited coating and oil spray layer on the surface of materials by water washing and rapid friction.

After the above process, the raw materials with single material and basically the same color are obtained; after the raw materials are batched, each batch is tested for performance. Then according to the customer’s requirements for product performance and color, the raw materials are modified and color matching granulation is carried out. After passing the inspection, the products will be delivered to customers. The waste water generated in the whole production process is treated, purified and recycled. The waste gas is discharged by the waste gas treatment equipment and meets the national (GB 16287-1996) waste gas emission standard, which truly realizes zero pollution in production.

Bloom Eco is PCR Cosmetic Packaging & PCR Cosmetic Containers Manufacturer.

Showing all 37 results

-

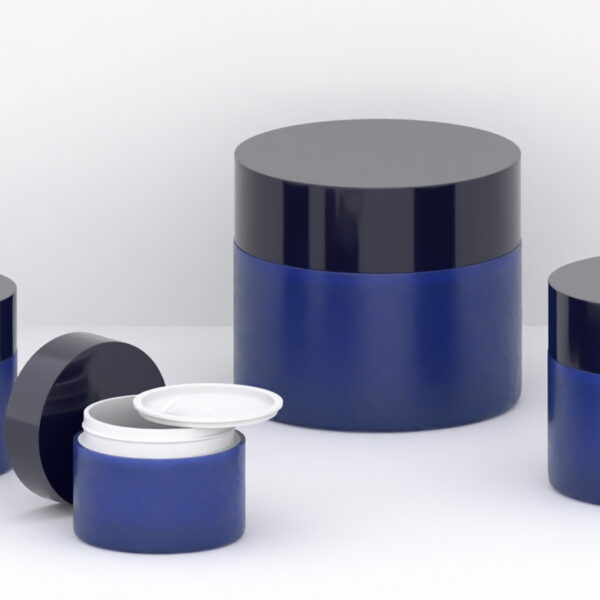

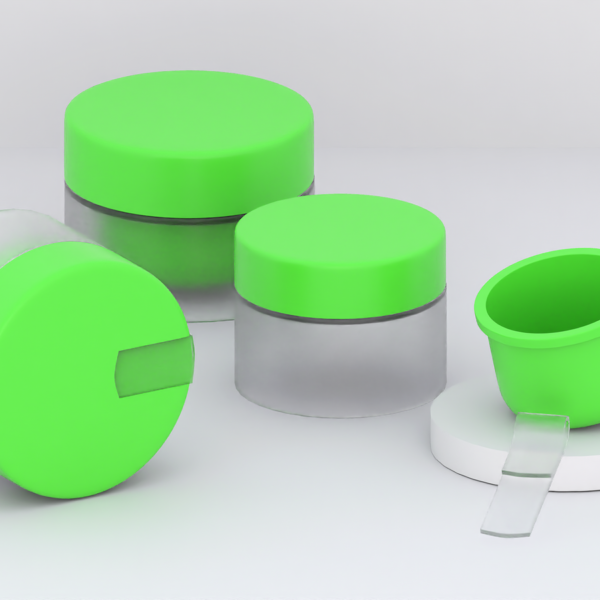

Mono PP & PCR Cream Jar CJ3001 | Mono Packaging

Inquiry Now -

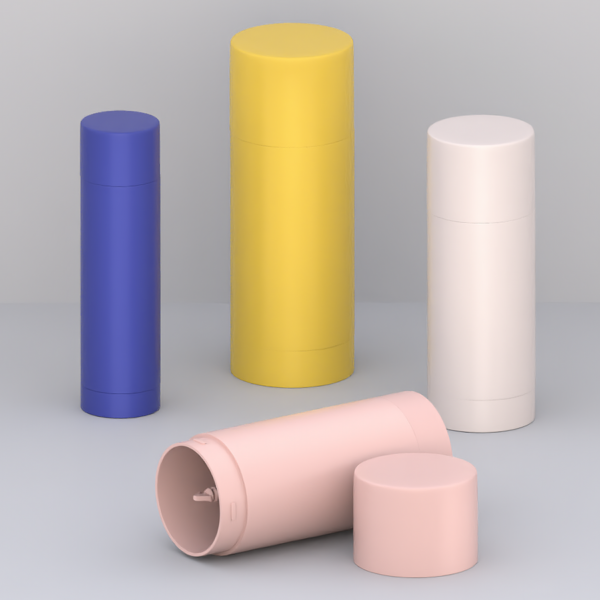

Mono PP & PCR Deodorant Stick DE1002 | Mono Packaging

Buy product -

Mono PP Cream Jar CJ1019 | Mono Packaging

Buy product -

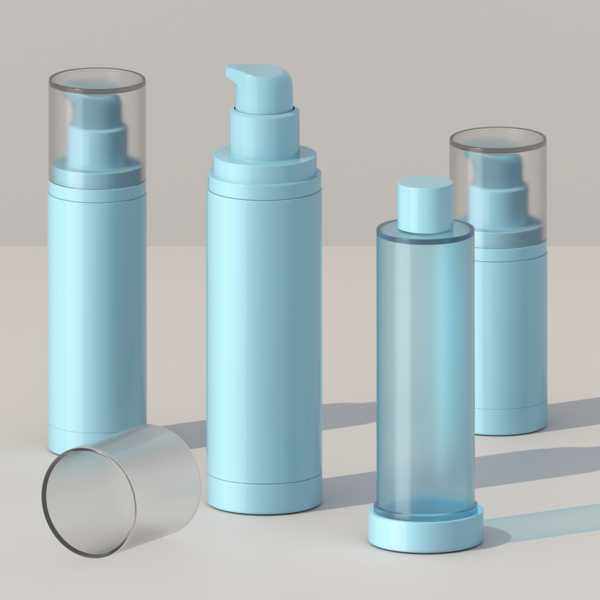

PCR Airless Bottle AB1015

Buy product -

PCR Airless Bottle AB1015M

Buy product -

Mono PP Cream Jar CJ2377 | Mono Packaging

Buy product -

Mono BIO-PE Bottle PB4001 | Mono Packaging

Buy product -

Metal Free PCR Airless Bottle AB1006

Buy product -

AB1026 PCR PP Airless Bottle

Buy product -

AB1037 PCR PP Airless Bottle

Buy product -

AB1040 PCR PP Airless Bottle

Buy product -

AB1044 PCR PP Airless Bottle

Buy product -

AB1052 PCR PP Airless Bottle

Buy product -

AB1062 PCR PP Airless Bottle

Buy product -

AB1105 PCR PP Airless Bottle

Buy product -

AB5015 PCR PP Airless Bottle

Buy product -

AB5016 PCR PP Airless Bottle

Buy product -

AB5018 PCR PP Airless Bottle

Buy product -

PCR Deodorant Stick DE1001 | Mono Packaging

Buy product -

PSC1002 PCR Deodorant | PCR Packaging

Buy product -

PSC1003 PCR Deodorant | PCR Packaging

Buy product -

PSC1004 PCR Deodorant | PCR Packaging

Buy product -

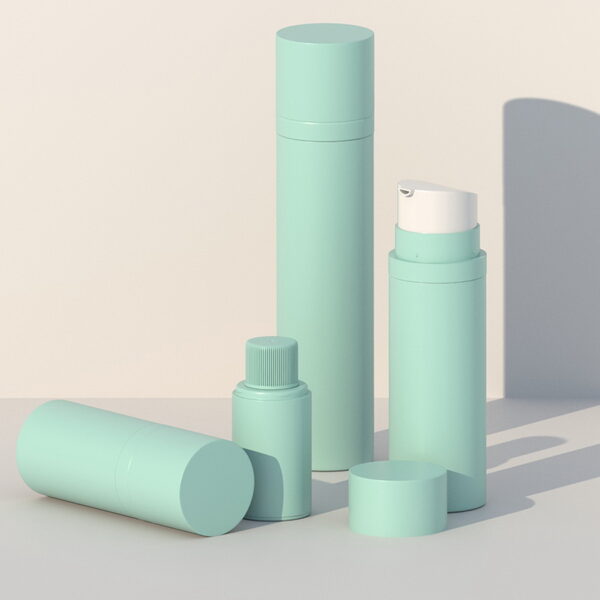

Refillable Airless Bottle AB1023

Buy product -

Refillable Airless Bottle AB1072

Buy product -

Refillable Airless Bottle AB2010

Buy product -

Refillable Airless Jar CJ9005

Buy product -

Refillable Cream Jar CJ1020

Buy product -

Refillable Cream Jar CJ1023

Buy product -

Refillable Cream Jar CJ1022

Buy product -

Refillable Lotion Bottle LD1073

Buy product -

Refillable Mono PCR Cream Jar CJ1024

Buy product -

Refillable PCR Airless Bottle AB1069

Buy product -

Refillable PCR Airless Bottle AB2009

Buy product -

Refillable PCR Airless Bottle AB2011

Buy product -

Refillable PCR Cream Jar CJ1028

Buy product -

Refillable PCR Deodorant Stick DE1005

Buy product -

Refillable PCR Deodorant Stick DE1008

Buy product