Nowadays, the big topic of sustainable development has become a must for everyone!

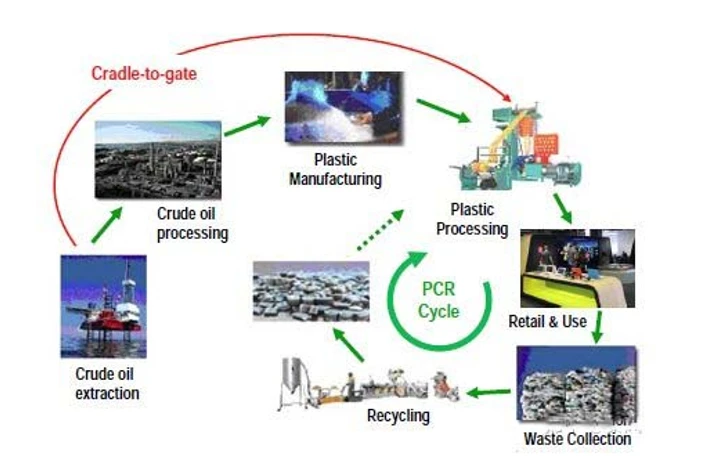

PCR, I’m sure you’ve become familiar with in recent years, is a kind of “recycled plastic”, the full name of Post-Consumer Recycled Material, that is, post-consumer recycling.

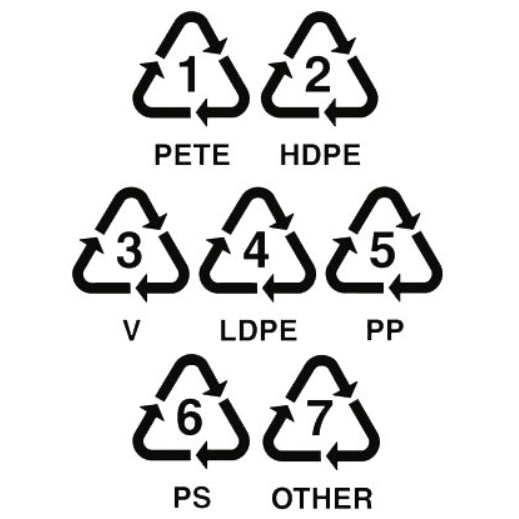

First of all, it is important to know that PCR is “extremely valuable”. Usually, after the circulation, consumption and use of waste plastics “PCR”, after physical or chemical recycling, can be turned into valuable industrial production materials, to achieve resource recycling. For example, PET, PE, PP, HDPE and other recycled materials from the usual lunch boxes, shampoo bottles, mineral water bottles, washing machine drums and other waste plastics produced by everyone, after reprocessing, can be used to manufacture new packaging materials of plastic raw materials. Since PCR comes from post-consumer, if not properly treated, it will inevitably have the most direct impact on the environment, so PCR is one of the recycled plastics currently promoted by brands.

According to the source of recycled plastic, recycled plastic can be divided into PCR and PIR.

PIR is called Post-Industrial Recycled material, that is, industrial plastic recycling, its source is generally the factory injection molding products produced by the water mouth, sub-brand, residual products, etc., due to the industrial production process or process of materials, commonly known as water mouth material, waste. It is directly recycled from the factory and reused.

In terms of recycling volume, PCR has an absolute advantage in terms of quantity; in terms of reprocessing quality, PIR plastic has an absolute advantage. Strictly speaking, both PCR and PIR plastics are recycled plastics that have been mentioned in rubber and plastic circles.

So, why do people choose to use PCR?

- PCR plastic is one of the important directions to reduce plastic pollution and help “carbon neutral”

Through the unremitting efforts of several generations of chemists and engineers, plastics produced from oil, coal and natural gas have become essential materials for human life because of their light weight, durability and beauty. However, the massive use of plastics has also led to the generation of large amounts of plastic waste. Post-consumer recycled (PCR) plastics have become one of the most important directions to reduce environmental pollution from plastics and help the chemical industry move toward “carbon neutrality”.

By mixing recycled plastic pellets with virgin resins, a variety of new plastic products can be made. This approach not only reduces carbon dioxide emissions, but also reduces energy consumption.

- Use PCR plastic to further promote waste plastic recycling

The more companies use PCR plastics, the greater the demand will be, which will further enhance the recycling of waste plastics and will gradually change the model and business operation of waste plastics recycling, meaning less waste plastics will be landfilled, incinerated and exist in the natural environment. - Policy to promote PCR plastics is opening up policy space

In Europe, the EU plastics strategy, the UK and Germany and other countries plastic and packaging tax legislation. For example, the UK Revenue and Customs issued a “plastic packaging tax”, less than 30% of recycled plastic packaging tax rate of 200 pounds per ton. Taxes and policies have opened up the demand for PCR plastics.

What industry giants have recently added PCR plastics to their portfolio?

The majority of PCR plastic products on the market are still mainly physically recycled, but more and more international chemical companies are keeping up with the development and application of chemically recycled PCR plastic products, hoping to achieve “carbon reduction” while ensuring the same performance of recycled materials as raw materials.

BASF Ultramid recycled material receives UL approval

BASF’s Ultramid Ccycled recycled polymer from its Freeport, Texas, plant in the U.S. has received certification from Underwriters Laboratories, Inc.

According to UL 2809, Ultramid Ccycled polymer, which is recycled from post-consumer recycled (PCR) plastics, can be used to meet recycled content standards using a mass balance system. BASF is researching new chemical processes to continue converting some waste plastics into new, valuable raw materials. This approach reduces greenhouse gas emissions and fossil raw material inputs, while leaving product quality and performance intact.

Randall Hulvey, Business Director, BASF North America: “Our new Ultramid Ccycled grade offers the same high mechanical strength, stiffness and thermal stability as our traditional grades, plus it will help our customers achieve their sustainability goals.”

Unilever: spice range switches to rPET, becomes UK’s first 100% PCR food brand

Unilever’s (Unilever) condiment brand Hellmann’s has switched to being made from 100% post-consumer recycled PET (rPET) and is launching in the UK. Unilever says that if the range were to switch to rPET in its entirety, it would save around 1,480 tonnes of raw materials per year.

Nearly half (40%) of Hellmann ‘ s products are already made with recycled plastic and hit the shelves in May. The company plans to switch the entire range to recyclable plastics by the end of 2022.

Andre Burger, vice president of Unilever’s food division in the UK and Ireland, commented, “Our Hellmann ‘s condiment bottles are the first food brand in the UK to use 100% post-consumer recycled plastic, and while there have been challenges in making this switch, these experiences will enable us to accelerate other Unilever food brands to to use more recycled plastic.”

-

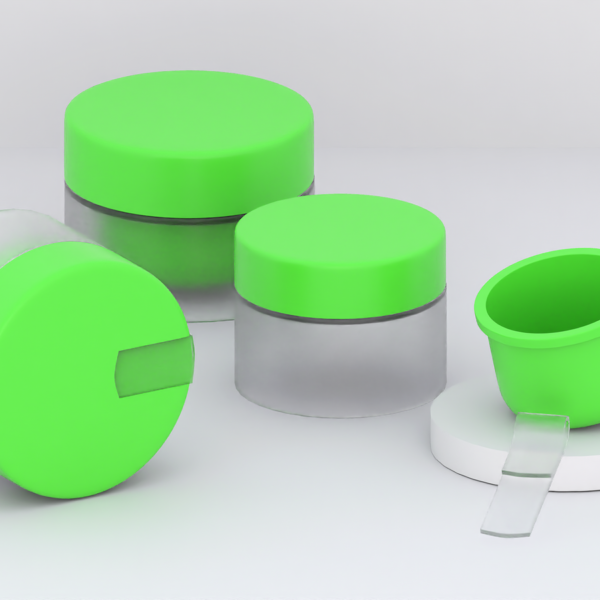

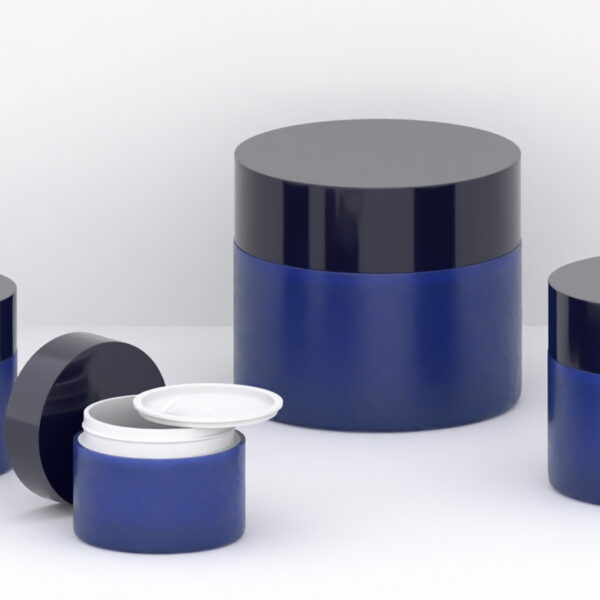

Refillable Cream Jar CJ1023

Refillable Cream Jar CJ1023 -

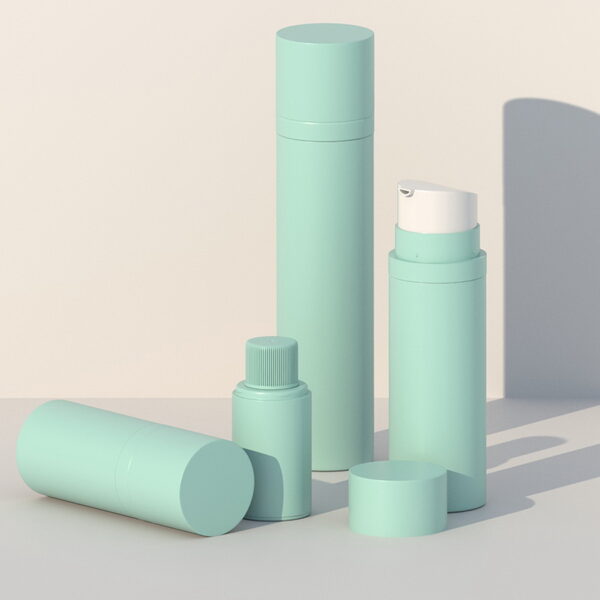

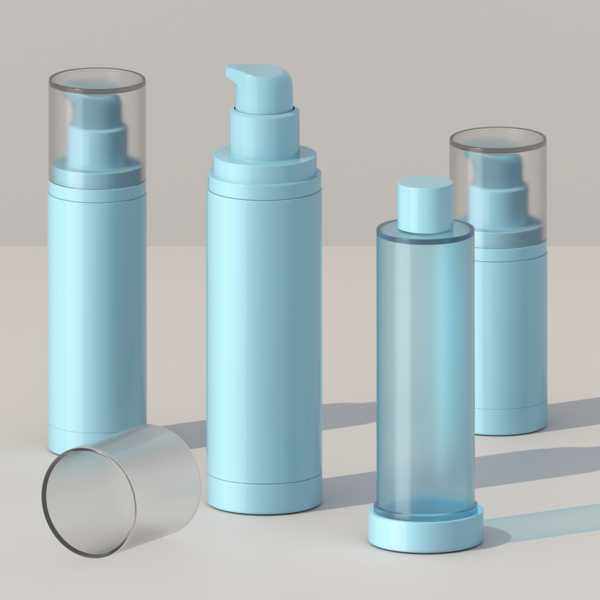

Refillable Airless Bottle AB1072

Refillable Airless Bottle AB1072 -

Refillable Cream Jar CJ1020

Refillable Cream Jar CJ1020 -

Refillable Airless Bottle AB1023

Refillable Airless Bottle AB1023 -

Refillable Airless Bottle AB2010

Refillable Airless Bottle AB2010 -

Refillable PCR Airless Bottle AB2011

Refillable PCR Airless Bottle AB2011 -

Refillable PCR Cream Jar CJ1028

Refillable PCR Cream Jar CJ1028 -

Refillable PCR Airless Bottle AB2009

Refillable PCR Airless Bottle AB2009 -

Mono PP & PCR Cream Jar CJ3001 | Mono Packaging

Mono PP & PCR Cream Jar CJ3001 | Mono Packaging -

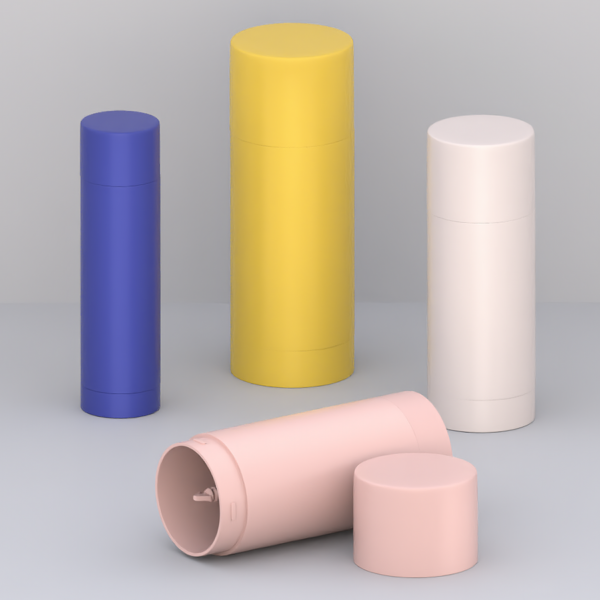

PCR Deodorant Stick DE1001 | Mono Packaging

PCR Deodorant Stick DE1001 | Mono Packaging -

PCR Airless Bottle AB1015M

PCR Airless Bottle AB1015M -

PCR Airless Bottle AB1015

PCR Airless Bottle AB1015